The Digital Shift in Manufacturing

The manufacturing industry is undergoing a significant transformation, and companies that fail to adapt risk losing their competitive edge. Today’s B2B buyers expect the same seamless digital experiences they encounter in B2C transactions. They want instant access to product information, self-service options, and a streamlined purchasing process—without having to rely on a sales representative for every inquiry.

Many manufacturers are still operating with outdated digital systems, making it difficult for customers to find the information they need, configure products, or place orders efficiently. This friction in the buying journey can lead to lost opportunities, longer sales cycles, and frustrated customers.

Enter Digital Experience Platforms (DXPs). These platforms are revolutionizing the way manufacturers manage content, product information, and customer interactions. By integrating websites, portals, self-service tools, and digital assets into a unified system, DXPs help manufacturers deliver personalized, efficient, and scalable digital experiences.

If your customers still have to call your sales team for basic product details, your digital experience is holding your business back.

So, what exactly is a Digital Experience Platform, and why does it matter in manufacturing? Let’s break it down.

What is a Digital Experience Platform (DXP)?

A Digital Experience Platform (DXP) is an integrated system that connects content management, digital assets, product information, and customer portals into a seamless digital experience. Unlike traditional Content Management Systems (CMS) or Enterprise Resource Planning (ERP) solutions, which focus primarily on content storage or operational efficiency, a DXP prioritizes the end-user experience while maintaining back-end efficiency.

For manufacturers, this means a single platform where product data, marketing materials, eCommerce functionality, and customer support tools work together to streamline operations and improve engagement.

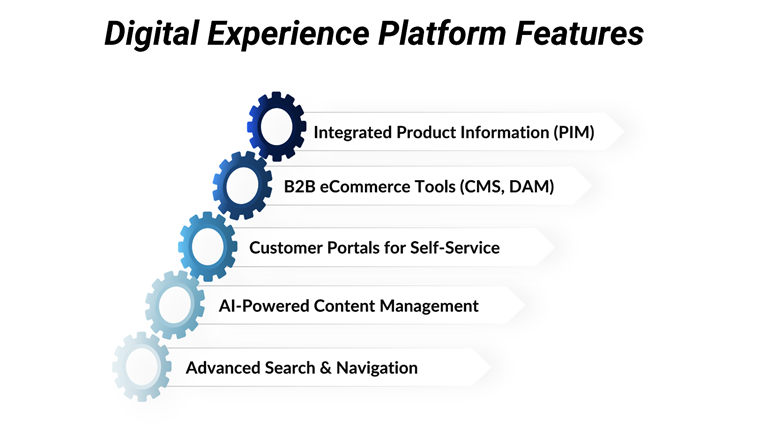

Key Functions of a DXP for Manufacturers

- Centralized Product Information Management (PIM)– Ensures accurate, up-to-date product details across all digital channels.

- AI-powered Content Personalization– Delivers relevant product recommendations, technical documents, and customer-specific pricing.

- Integrated B2B eCommerce & Customer Portals– Enables self-service ordering, account management, and real-time order tracking.

- Seamless Omni-Channel Experiences– Provides a unified experience across desktop, mobile, and self-service portals.

Imagine a manufacturing company where product specifications, marketing assets, and customer support resources all live in one place, accessible 24/7.Instead of customers waiting for a sales rep to email a PDF or answer a question, they can instantly find what they need, configure a product, or place an order—without roadblocks.

Why are manufacturers making the switch now?

The shift to DXPs isn’t just a passing trend—it’s becoming a necessity. Let’s explore why manufacturers are rapidly adopting these platforms and how they are reshaping the industry.

Why Manufacturers Are Adopting DXPs

The rapid adoption of Digital Experience Platforms (DXPs) in manufacturing is driven by a fundamental shift in B2B buyer expectations, data management challenges, and the need to reduce costs. Manufacturers that embrace DXPs are gaining a competitive advantage by providing a seamless digital experience, automating product data management, and empowering customers with self-service tools.

1. B2B Buyers Expect a Better Digital Experience

Today’s B2B buyers prefer self-service over talking to a sales rep—They want instant access to product details, pricing, specifications, and documentation without having to send emails or make phone calls.

If your website requires customers to search multiple places for product details, manuals, and pricing, you risk losing them to competitors who offer a more streamlined experience. A DXP centralizes all product information, ensuring buyers can easily find what they need—whenever and wherever they need it.

Example: Think of a manufacturing customer looking for product specs and installation guides at 10 PM—if your website doesn’t have it, they may look elsewhere.

2. Managing Product Data is a Nightmare Without One

Manufacturers manage hundreds or even thousands of SKUs, with frequent updates to product specifications, compliance documentation, and pricing. Yet, many still rely on disconnected spreadsheets, outdated PDFs, and manual updates across multiple platforms—leading to errors, inconsistencies, and inefficiencies.

A DXP automates product updates across all channels, ensuring that websites, eCommerce platforms, and customer portals always display accurate, up-to-date product information.

Example: A manufacturer using a DXP can update a product description once, and it automatically syncs across their website, eCommerce store, and customer portal—eliminating the need for manual updates.

3. Customer Portals & Self-Service Reduce Costs

Manufacturers spend a significant amount of time and resources answering repetitive customer inquiries about product specifications, order tracking, and technical documentation. Instead of forcing customers to call or email for answers, a DXP-powered customer portal enables them to self-serve and find the information they need in real time.

This reduces customer service costs while improving efficiency and satisfaction.

Example: Instead of calling to request a product manual, a customer logs into a manufacturer’s portal, downloads the document, and tracks their order—all without contacting customer support.

How Do You Know If Your Company Needs a DXP?

If your manufacturing business is struggling with disconnected systems, slow customer response times, or inaccurate product data, it may be time to consider a DXP. Next, we’ll explore the signs that indicate your company is ready for this transformation.

Signs Your Manufacturing Business Needs a DXP

If your manufacturing company is still relying on manual processes, disconnected systems, and outdated digital experiences, you could be losing potential customers and slowing down operations. Here are key signs that indicate it’s time to adopt a Digital Experience Platform (DXP):

Your product information is scattered across multiple systems and is hard to manage.

If you’re juggling spreadsheets, ERP systems, and outdated PDFs, keeping product data accurate and consistent is a challenge. A DXP centralizes product information, ensuring updates are automatically reflected across all digital channels.

Your customers still rely on emails or calls to get basic product details.

Modern B2B buyers expect instant access to product specs, pricing, and manuals—if they have to call a sales rep for information, they may look elsewhere. A DXP allows customers to self-serve through a website or portal, reducing response times and improving customer satisfaction.

Your website lacks a modern B2B eCommerce or self-service portal.

If your website is just a static product catalog with no B2B eCommerce features, quote request forms, or order tracking, you’re missing out on potential revenue. A DXP integrates B2B eCommerce and customer portals, creating a seamless buying experience.

You struggle with scaling content and keeping it consistent across multiple platforms.

Manually updating product descriptions, technical documents, and marketing materials across multiple channels is time-consuming and prone to errors. A DXP automates content distribution, ensuring accuracy and consistency across all digital touchpoints.

If you checked even one of these, it’s time to explore a DXP.A Digital Experience Platform can help streamline operations, improve customer engagement, and future-proof your manufacturing business.

How to Choose the Right DXP for Your Business?

Not all DXPs are created equal. The right solution should align with your business needs, technical capabilities, and customer expectations. Let’s explore the key factors to consider when selecting a DXP for your manufacturing company.

What to Look for in a Manufacturing DXP

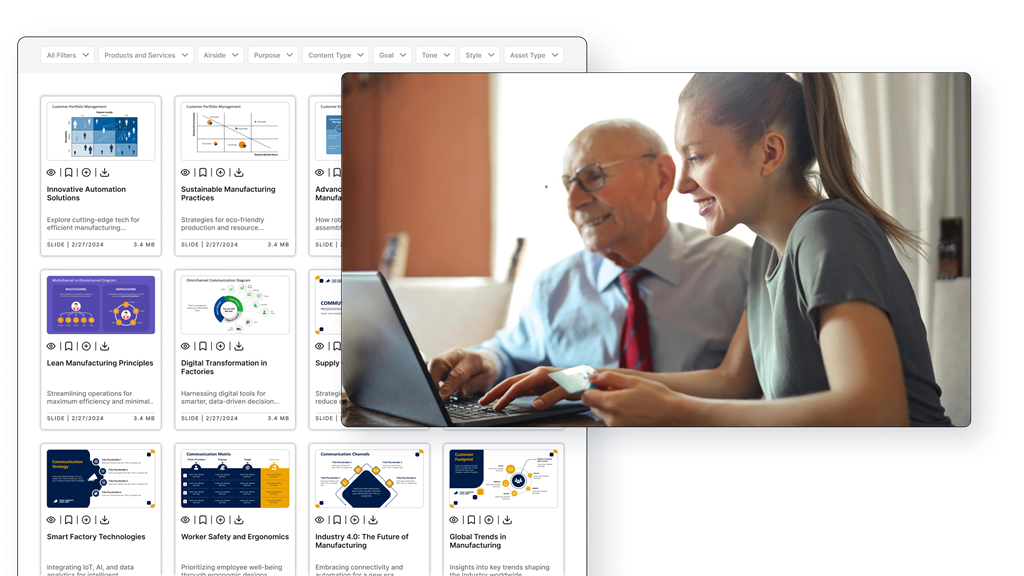

Not all Digital Experience Platforms (DXPs) are built the same, and manufacturers have unique needs that go beyond basic content management. When evaluating a DXP for your business, look for features that streamline operations, enhance customer experiences, and support long-term growth.

Key Features to Consider

- Integrated Product Information Management (PIM)

A strong DXP should have a built-in PIM to keep all product data centralized, accurate, and easily accessible. This ensures that product details, specifications, and pricing remain consistent across all digital channels. - B2B eCommerce Tools

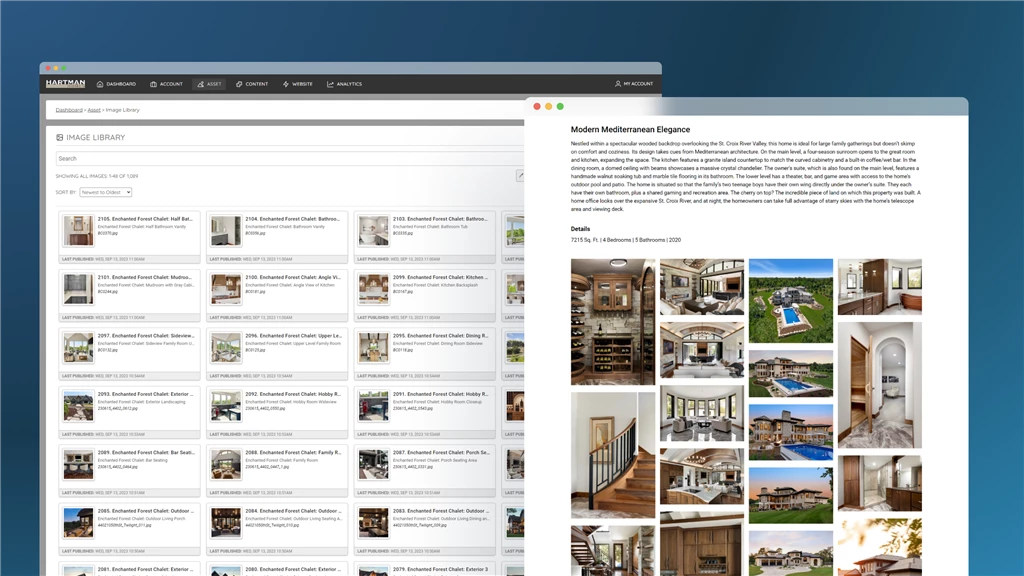

A manufacturing-focused DXP should support online ordering, quote requests, and account-based pricing. Customers should be able to place orders, check order history, and manage their accounts without needing to contact sales. - Customer Portals for Self-Service

A DXP should enable manufacturers to offer a seamless self-service experience. Buyers should be able to access product manuals, technical documents, order tracking, and support resources on demand. - AI-Powered Content Management

The best DXPs use AI to personalize content, recommend relevant products, and automate updates for different customer segments. This improves engagement and ensures that the right information reaches the right audience at the right time. - Advanced Search & Navigation

- A DXP should include intelligent search functionality that enables customers, sales teams, and partners to quickly find the exact product information, documentation, or resources they need. Features like faceted search, AI-driven recommendations, and dynamic filtering improve user experience and reduce time spent searching for critical details.

A good DXP doesn’t just manage content—it makes it easier for your customers to do business with you. By ensuring accurate product data, enabling self-service, and streamlining transactions, the right DXP can become a powerful driver of efficiency and growth.

Final Thoughts on Digital Transformation in Manufacturing

Manufacturers that embrace digital transformation are positioning themselves for long-term success. Next, let’s look at how a DXP can future-proof your business and give you a competitive edge in the evolving B2B landscape.

The Future of Manufacturing is Digital

Digital transformation is no longer optional—it’s a necessity for manufacturers looking to stay competitive. Companies that embrace Digital Experience Platforms (DXPs)gain a significant advantage by streamlining operations, reducing costs, and enhancing customer experiences.

Manufacturers that continue to rely on manual product data management, outdated systems, and sales calls for basic customer interactions risk falling behind. Today’s B2B buyers expect self-service options, real-time product information, and seamless digital experiences across all channels. A DXP eliminates friction in the buying process, helping manufacturers improve efficiency and drive growth.

If your business is struggling with disconnected systems, inefficient workflows, or poor customer engagement, now is the time to take the next step.

Is your business ready? KNVEY helps manufacturers modernize their digital experience by providing an all-in-one platform for product information management, B2B eCommerce, customer portals, and AI-driven content management.